The cover on the upper deck of Morning Star is the perfect spot for sea gulls to land, have a leisurely meal of mussels, or other products of the sea, or of nearby garbage cans, and then leave their calling card. I cannot tell you how many times I have washed the cover down. A simple hosing down is ineffective in cleaning the crud off. And so I declared war on the sea gulls.

My first attempt at keeping the gulls off the cover was aluminum pie pans on cord, strung in various ways across the cover. This was not the way to go. I quickly found that to make the pie pans work I needed a spiders web of cord to hold them in the right position as they always seemed to end up just dangling over the edge. Plus the put up, take down time was excessive.

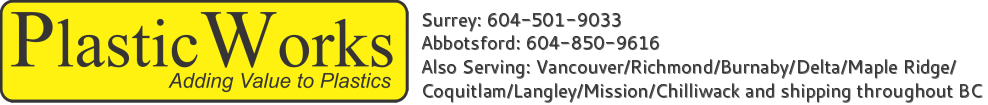

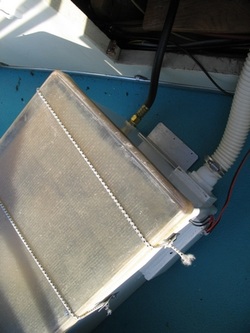

My second attempt was to make some 2” thick plastic blocks by bolting together 1/2” black Starboard. These blocks could then be attached to the 1” railing going around the top deck of the boat. Holes were then drilled into the block to receive 1/4” round fiberglass rod. The holes were drilled at angles so when the fiberglass rods were inserted they would fan out above the boat cover, preventing the sea gulls from landing. And – it worked! The rods kept the gulls off and my cover remained clean. No longer did I have to remove, roll up, and store a shitty cover whenever I took the boat out. But I was never very satisfied with this solution, which is why it never made it to this blog. While the Starboard blocks could remain on the railing all year, they did not look good, and they had to be removed for the winter cover to be put on, and they were bulky and tough to find a place to store.

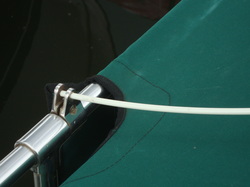

After proving up the system I did modify the side to side rod by cutting it in two, and then using a plastic block with a hole drilled in it to join the two pieces together. This shortened the overall length when taken down and folded, and made storage easier.

So come on in, grab some chunks of plastic and let your mind free range. And remember our new address Surrey Plasticworks Ltd now at 12198 86th Ave, Surrey BC.

RSS Feed

RSS Feed